No products in the cart.

All products

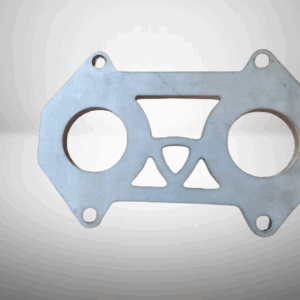

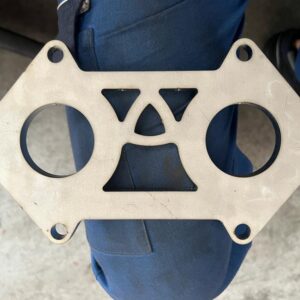

13B-REW Oil Filler Neck – High-Temp Nylon + Carbon Fiber

119,99 €

people are viewing this right now

Guaranteed Safe Checkout

- Free worldwide shipping on all orders over $100

- Delivers in: 3-7 Working Days Shipping & Return

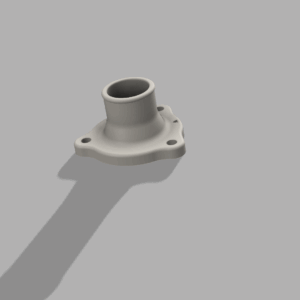

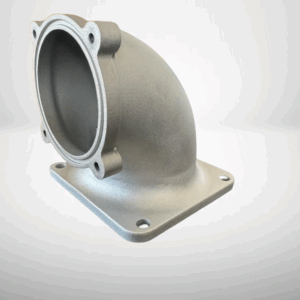

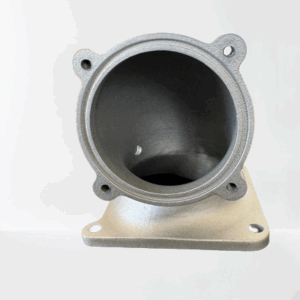

Upgrade your rotary engine with our precision-engineered oil filler neck, designed for performance, space efficiency, and high-temperature reliability.

This part is 3D printed using a high-performance blend of carbon fiber and high-temperature nylon, offering a lightweight yet extremely durable alternative to the bulky OEM design. Ideal for engine bays where space is limited, especially in RX-8 13B swap applications.

Key Features

| Feature | Description |

|---|---|

| Material | High-temp nylon infused with carbon fiber |

| Manufacturing | Precision 3D printed |

| Design | Compact, low-profile shape frees up engine bay space |

| Fitment | Optimized for RX-8 13B engine swaps |

| Ports | M10 barb port for catch cans, vacuum lines, or intake recirculation |

| Heat Testing | Each unit is tested at high temperature to ensure structural integrity |

| Production Time | Built to order – please allow 2 business days for manufacturing |